Customer Success Story

Energy and marine solutions provider MHB sets sail with expansive AI-enabled network

Malaysia Marine and Heavy Engineering (MHB) stands as a globally recognized leader in energy and marine solutions, catering to a diverse array of offshore and onshore facilities and vessels. With a track record spanning 50 years, MHB has consistently delivered integrated and complex solutions to international oil & gas clients. MHB also owns three dry docks which are amongst the largest dry docks in Southeast Asia.

MHB aims to have world-class technology as it moves from paper-based processes to digital workflows that will speed project completion. The company is using AI-driven networking from Juniper to provide fast, reliable connectivity across its massive shipyard to support its digital transformation.

Overview

| Company | Malaysia Marine and Heavy Engineering (MHB) |

| Industry | Energy and Utilities |

| Products used | AP32, EX2300, EX4650, EX4400, EX4100, Wireless (Wi-Fi) Assurance, Wired Assurance |

| Region | APAC |

500 acres

Fast, reliable Wi-Fi covering the largest fabrication yard in Malaysia and one of the largest dry docks in Southeast Asia

Digitalization

Infrastructure technology refresh to support business transformation of MHB’s Heavy Engineering and marine solution.

Foundation

For digital transformation of heavy engineering in oil and gas industry

Adding connectivity across Malaysia’s largest fabrication yard

MHB offers a full range of construction and engineering services for the offshore and onshore oil and gas industry, from engineering design and procurement to construction, installation, and commissioning. Its diverse projects include the construction of production topsides, process modules, turrets, floating production systems, buoy systems, and mobile offshore storage units. MHB also supports comprehensive ship repair and refurbishment.

At its fabrication yard, the company had paper-based ops and aging tech that was not able to capture business needs as the company returned to growth after several difficult years of low oil prices and the economic downturn.

“We needed more AI, more IoT, and a transformation of our infrastructure,” explains Raslan Rahim, Head of ICT, Malaysia Marine and Heavy Engineering.

To facilitate digital transformation, MHB needed a network that could support digitalization of its workflows, including its daily work checklist system for marine repair project monitoring and tracking. Fast, reliable Wi-Fi would also lay the foundation to gather machine data to be used for predictive maintenance and to optimize heavy machinery usage.

Ship-shape network connectivity accelerates workflow and revenue

“Our sprawling yard spans 500 acres,” says Raslan. “We had to figure out how to install Wi-Fi access points in the middle of nowhere.”

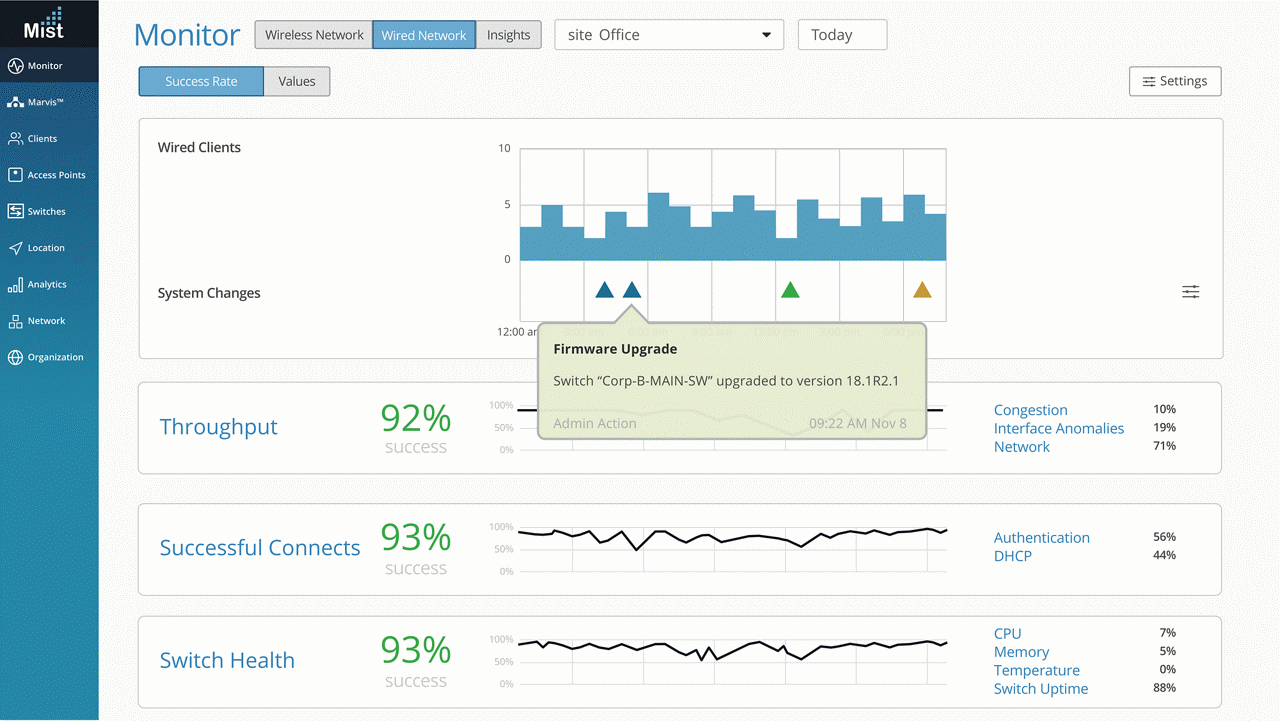

A private LTE and fiber optics network seamlessly connects the MHB yard with its data center. In order to provide comprehensive coverage for the fabrication yards and dry docks, MHB utilizes Juniper’s access points, all integrated within a private mobile network infrastructure. These Juniper access points and switches work in conjunction with the Juniper Mist cloud architecture, driven by Mist AI™, to deliver optimized network user experiences to MHB staff on the yard and in the office.

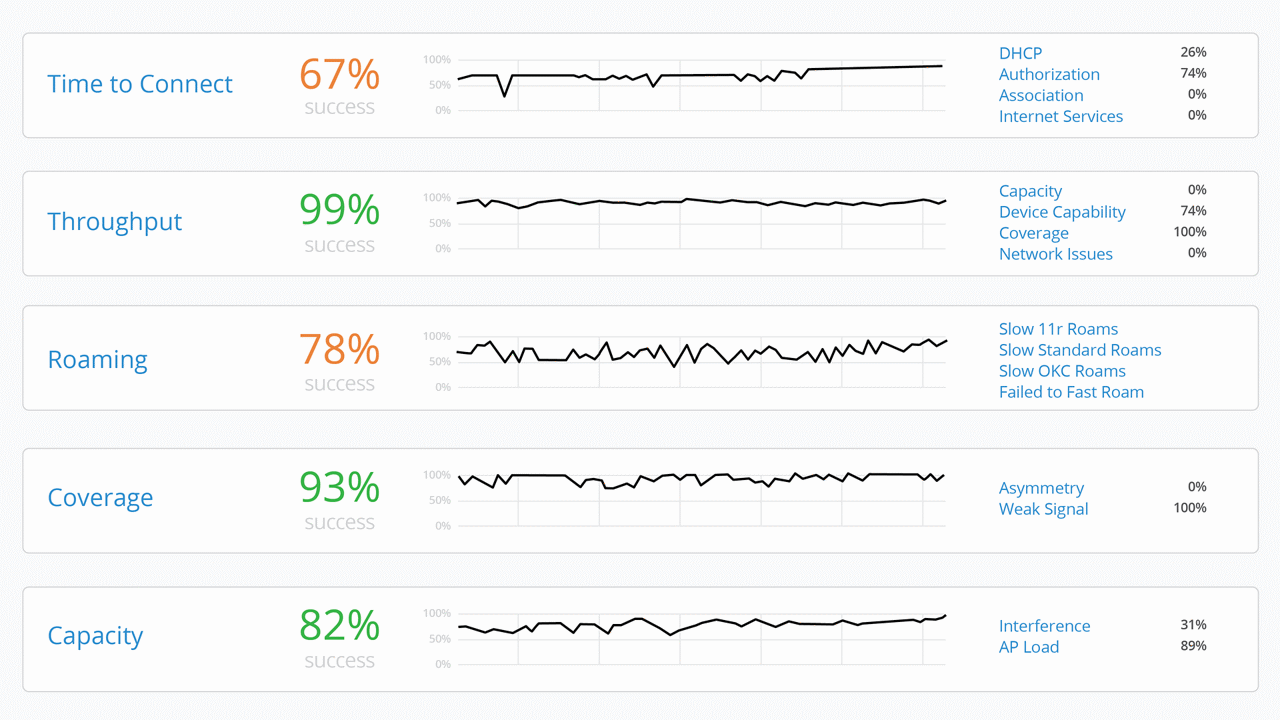

The IT team has quickly come to rely on Juniper’s AI-driven networking tools, including Juniper Mist Wi-Fi Assurance, Mist Wired Assurance, and Marvis Virtual Network Assistant, for visibility into the network user experience and proactive problem identification and resolution. With Juniper, the IT team resolve network problems before they impact the user—or the business workflows.

AI-enabled infrastructure paves the way for smart tech

The Wi-Fi is the foundation of MHB’s digital daily work checklist system that is used to monitor and track marine repairs. MHB is seeing a reduction in work turnaround times and an increase in accuracy of work done in its marine operations and plans to continue its momentum of digitalization to further improve the accuracy and precision of repair work conducted and increase the efficiency of its repair processes.

“Before Juniper Networks, we relied on paper checklists, and final approvals on jobs could take seven or eight days before reaching the client,” says Raslan. “With Wi-Fi connectivity, we can reduce the approval cycle, which means jobs can be completed faster. The faster we can complete jobs, the more ships that can come in, and the more revenue we generate.”

The Juniper network at MHB is an integral part of its 24x7 operations—and connectivity helps keep projects on schedule. “It takes two to three years to build an oil and gas structure, and the timeline is tight. Any delays in workflow due to a network outage can cost massive financial setbacks if the project is delivered behind schedule,” he says.

As a next step, Raslan plans to explore the addition of connected smart devices and IoT sensors to equipment like cranes, trucks, and machinery to optimize utilization and track their location. “We can use these smart technologies now because we have a strong network infrastructure,” Raslan adds.

Published September 2023